NI003, my 3rd automatic

robot vehicle

Year:

2002-2006 (not done yet)

†

††

††

†This is my biggest project, and is also my

diplome-project.

† The robot has to be able to: sensing small

obstackles, sensing the sideof the table (end of the ground) and the barriers,

sensing the turning angle, and the path, and also sensing activities in the

room. It has to can moving itself, and the small obstackles, like dices.

Sensors:

-Laser

radar: to sense the obstacles, and barriers.

-Infrared

reflective object sensors: to sense the ground, avoiding the falling down from

the table, which means the ground for the robot.

-MEMS

Accelerometers: to sense the acceleration in two directions, to compute travel

from the starting point.

-Knocking

sensor: it is a microphone, with some circuits, to sense, when somebody drops a

dice.

The

mechanics:

†††††††††††

†††††††††††  †

†

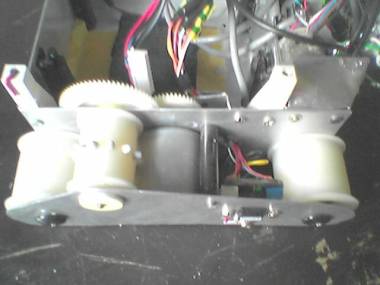

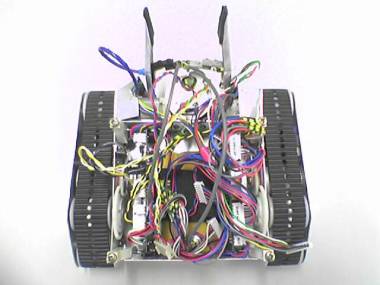

† The robot has two caterpillars, because this

way it can turn in place. These caterpillars was made from shoe-sole material,

at home. These have 6 wheels, what not I made, but a turner made on a cnc-lathe

machine. The chassis was made from 1mm thick aluminum plate, at home, with

papercutting scissors!

† The cathing arms were made from aluminum

plate, some Lego parts, and cogs from audio casette recorders, and CD-ROMs. The

arm has 4 switches as way-end-sensors.

The

laser radar:

† I wouldnít like to put anything about hat,

because it is possible that I will try some patenting procedures for that

thing. But, I know, this is the most interesting, and most difficoult thing in

this project. Just some things: Ican measure distances, in many directions -i

hope with 3mm resolution- to build a radar image.

The

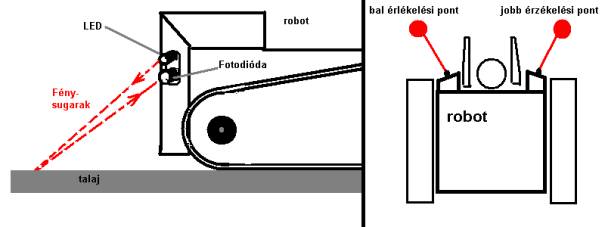

ground sensors:

†††

†††

It senses the

reflected and modulated signal from the IR-LED, through the reflection on the

surface of the ground. It senses in two directions, for the better safety. I

use TV remote controller receiver ic-s in the processing circuit. The sensors:

SFH481 IR LEDs, and BPW41 photodiodes. It eats 100mA. But it can be turn off,

because it is not needed when the robot doesnít move.

† Knocking sensors:

† Simple dynamic microphone, to hear when

somebody drops a dice. Because it will be a possible application for the robot,

to find the dice, and bring back to the origin.

† Accelerometers:

† If we can measure the acceleration, we can

compute the speed, with a simple numeric inthegral, with the DSP. If we know

the speed every time, we† can compute

the travel way in the same method. Then more simple to compute the position in

a table. So this is navigation. We measure acceleration at the x axis, to

compute linear moving, and measure acceleration in the y axis, to compute it to

angle-acceleration, and then to angular turning.

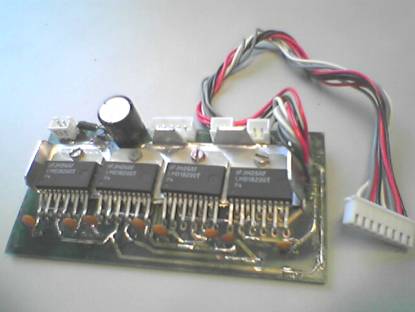

††Motor

driver circuits:

† I used four pieces of LDM18200Ts from

National. Using these is very easy. This motor driver is in a separate board,

and works in PWM mode. The arm needs just 6-10% duty cycle, but the driver

motors need 20-90%, depending on what do those: turning, or linear moving.

† Power supply system:

† The robotís circuits need a lot of vltages,

in numbers of power and noise levels. So there is a separate power supply

board, to produce that. It also does the accumulator-charging.

† †

† †

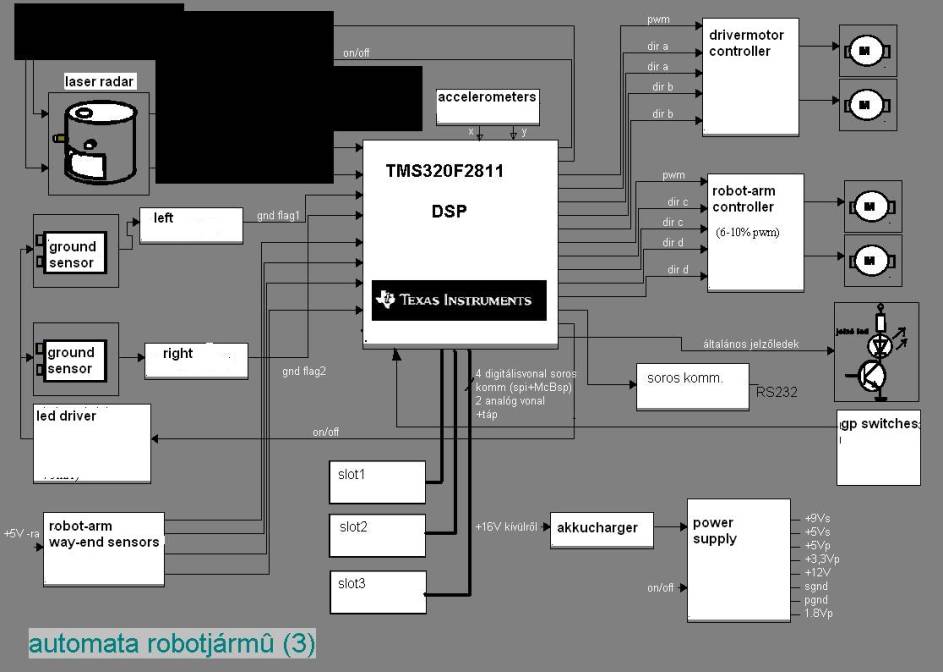

† Main control, and the whole electronic

system:

† The soul of the robot is the TMS320F2811 DSP

from the Texas Instruments. It runs on 100MHz. The original concept was that

the robot must do everything, without any human intervention, recognize

situations, an find solutions alone. There is an RS232 interface, for testing.

Testing the sensors, the sensor signal processing, an testing the control of

the mechanincs. It have to solve a complex task alone, like to finding the

dices, and bring those back to the origin, where it powered up at the first

time.

† The systemís block diagram:† (The black thing is the top secret thing J.)

the

mainboard: (the old at left, and the new at right)

†

†

The mainboard is a two layer-board, with

separate power and signal grounds, similar to the systems with analog and

digital grounds. There are both analog and digital, high current, and low

current, sensitive, and noisy circuits. So this is a nightmare about the aspect

of† signal integrity, and EMC, but this

makes the work more nice for the designer!

In several years, I designed and made many

printed circuit boards for the project:

†

†  ††

†† ††

†† ††

††

†

†  †††

††† †

†

†

†  ††

††

†

†  ††

†† ††

††

The most of them are only test circuits for the

separated functions of the robot. Some of them are home-made, but the recent

circuits are made by PCB manufacturers.

10.december.2005:

The tests

of the electronics system, and the repair of the hardware are full done, and

works fine. The laser radar is also works well. The semester is ending these

days, so the writing of the software is the following semesterís task. Some

little c programs are written, to control the mechanics, and some sensors. I

want to put these, as drivers, to a software system, with the real

time-operating system, the DSP/BIOS, what I will write. After that, I hope I

will finish the project with the auto-navigation and dice-handling until the

end of the next semester, to put in as a diploma.

16.march.2006:

The DSPís

ADC does not work well, and the electronics should to redesign to get better,

more recognizable radar images.

2. May,

2006:

I have

redesigned the board, with active filters as front-ends for the DSPís ADC. The

ADC now works fine and correctly already.

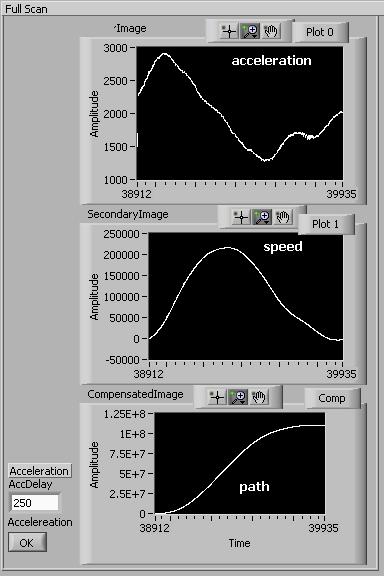

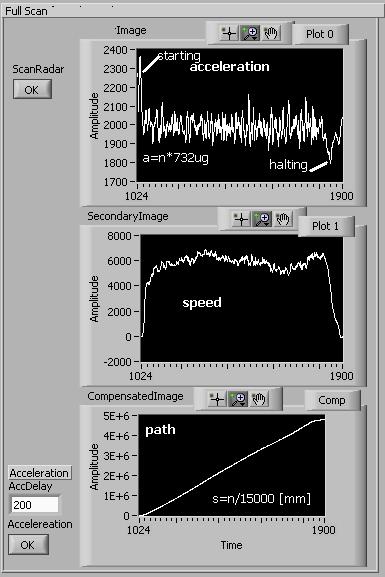

Accelaeration

sensing and speed/path calculating for the robot positioning: The robot is

remote-controlled by commands from the host computer. There are commands about

robot moving, positioning, where the robotís DSP will calcilate the path during

moving. It is good for linear moving, and for turning around the robotís center

poing.

Test

acceleration samples, with manual moving test††††††††††††††††††††††††††††† Test

acceleration samples, with automatic moving test†††††††††††

††††††

††††††

In the

second image, it is visible a vibration during the linear moving period. But,

the expected value of that is zero acceleration (calculated by a substraction

of the offset, the acceleration of the repose state).

24.05.2006

The

Bluetooth interface card has been done.

I work on

the configuring of the Bluetooth module, to enable the robot remote control,

via a radio link.

It took one

and a half days to design and build the card. I have used a WT12 standalone

Bluetooth module from the Bluegiga technologies (and Sero kft).

The

home-made Bluetooth card.

10.06.2006

The robot

works now as a remote controllable version, via Bluetooth, from the PC.

The

automatic control verion (I hope so) will work in the end of the year, or only

next year. I have to finish the radar hardware development, because this is the

key of the automatic control/navigation. It does not work correctly yet.

(Where is the dice? This is the big question,

what the robot will try to find out)